Pulse Jet Air Intake Filter (펄스젯 필터) 원리

HOW THE PULSEJET FILTER WORKS

Filtering out the dust.

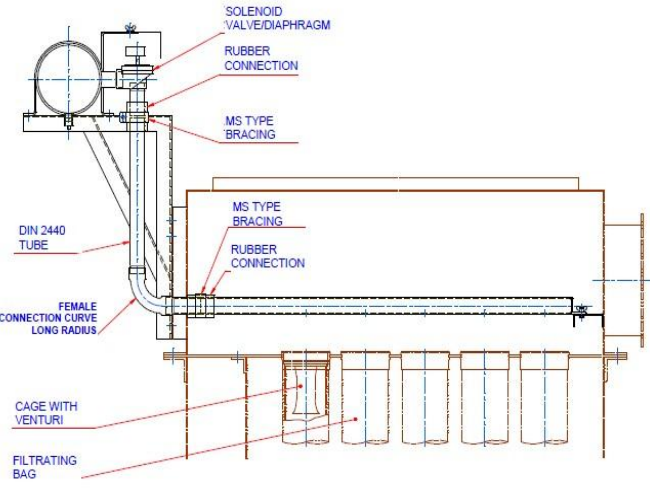

• As the dust-laden air enters the filter, fine particles are borne into the cartridge area. The air passes through the filter

media, depositing the dust on the outside of the filter. The filtered air continues up the inside of the cartridge into the

clean air plenum and then out of the filter housing. Cleaning the Filters

• Accumulated dust on the exterior of a filter is periodically

removed by directing a short pulse of compressed air down the inside of the cartridge. An aerodynamically designed

venturi at the top of each cartridge causes the pulse of compressed air to induce a flow of clean air into the

cartridge. A shock wave is set up that travels down the filter and hits a solid plate at the bottom. The shock wave

momentarily pressurizes the filter, stops the flow of dust-laden air into it and flexes the media; the effect is enhanced

by the plate at the bottom. The dust falls off, and drops to the open atmosphere.

• This instantaneous cleaning action proceeds row by row

while the flow of dust-laden air into the filter continues uninterrupted. Each row being cleaned is off-stream for

1/20th of a second (nominally); the entire media area of a pulsejet filter is in virtually continuous operation.

HOW THE PULSING AIR SYSTEMS OPERATES

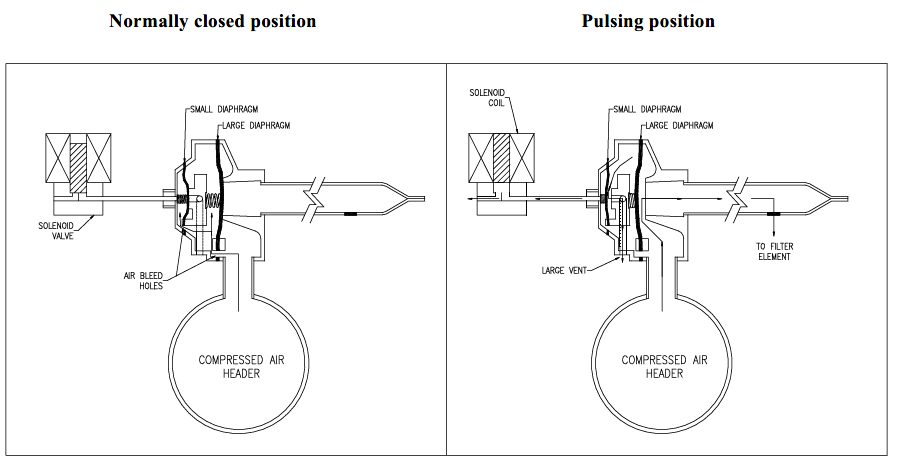

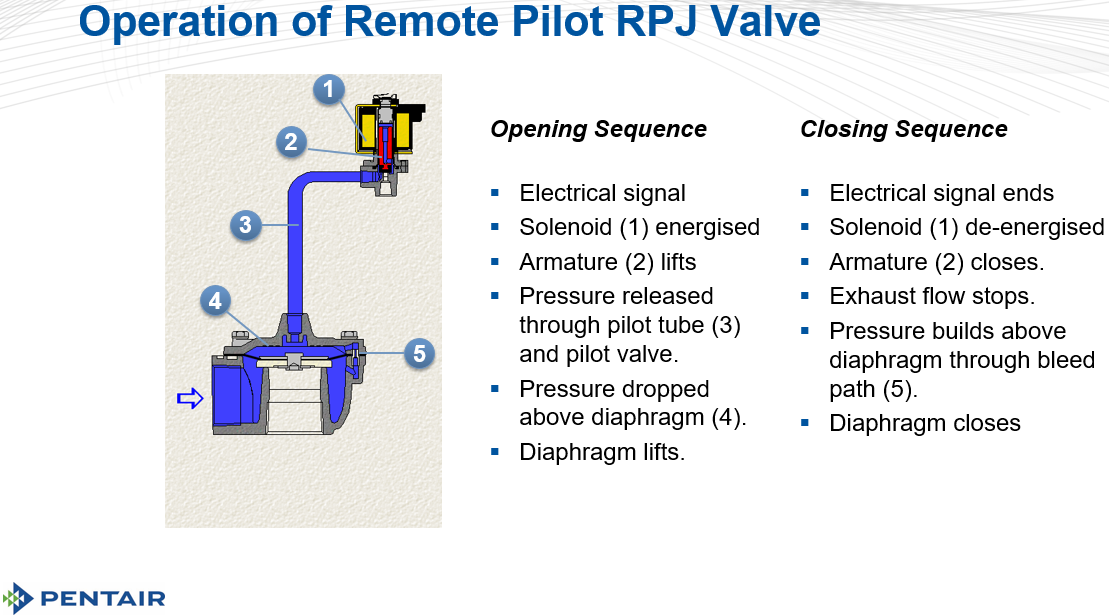

Normally Closed Position.

The solenoid armature blocks passage of compressed air from the pilot valve. Air bleed passages

provide equal air pressure on the left and right sides of each diaphragm. Since more area is

exposed to air pressure on their left sides, the diaphragms are pushed to the right. Springs assist

in holding the diaphragms in their closed positions.

Pulsing position.

The solenoid armature lifts off of its seat when the coil is energized by a 50-millisecond

electrical pulse from the timer. The pressure balance across the small diaphragm is upset as air

escapes through the pilot valve, causing the small diaphragm to open against spring. This action

uncovers the large diaphragm vent, and a pressure imbalance develops across the large

diaphragm. Unequal air pressure opens the large diaphragm against spring, uncovering the

blowpipe. Air from the compressed air header passes through the blowpipe to clean the filters.

When the solenoid armature returns to its seat (after 50 millisecond electrical pulse), pressure

balance is restored through the air bleed passages, and both diaphragms are closed again by

spring and pressure forces.